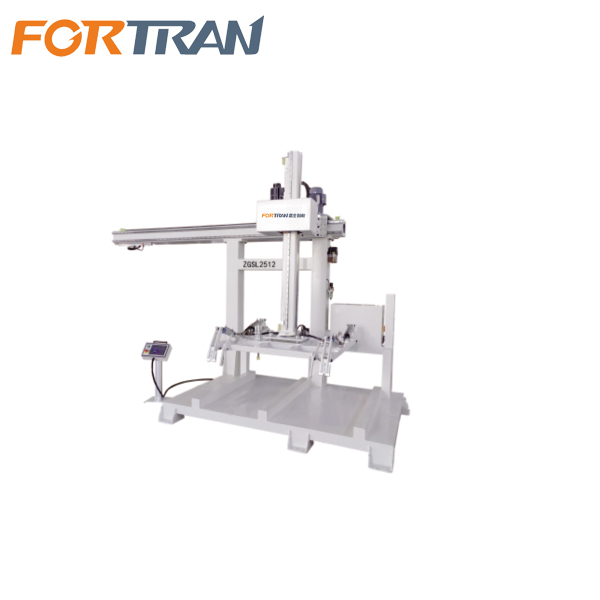

Four Station Panel Gantry Loading And Unloading MachineFour Station Panel Gantry Loading And Unloading Machine The innovative design of four workstation collaboration has redefined the material transfer mode in the production of panel furniture. The deep integration with edge sealing solutions not only achieves efficient feeding and quality control in the edge sealing process, but also connects multiple processes such as cutting, drilling, and quality inspection, building an intelligent production network of "material equipment data" interconnection. For enterprises pursuing mass customization production, this equipment is a key tool to improve order response speed, reduce production costs, and ensure product quality, providing solid support for the intelligent upgrading of the furniture manufacturing industry.

Four station panel gantry loading and unloading machineGantry Loading and Unloading MachinePanel Gantry Loading And Unloading MachinePanel Gantry Unloading MachineEmailMore