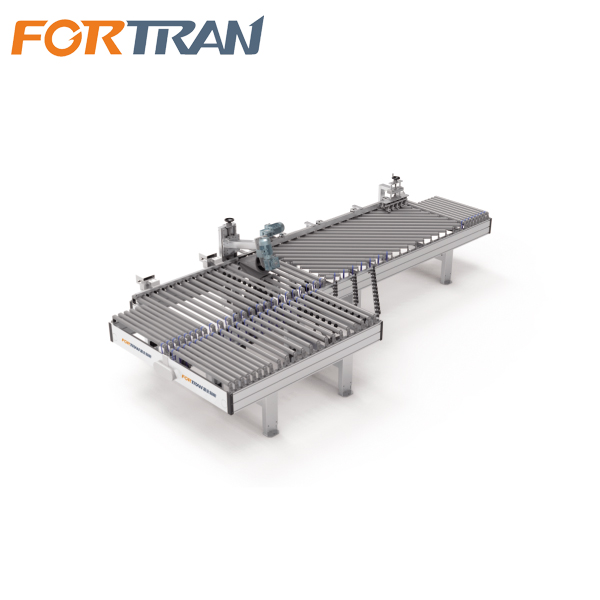

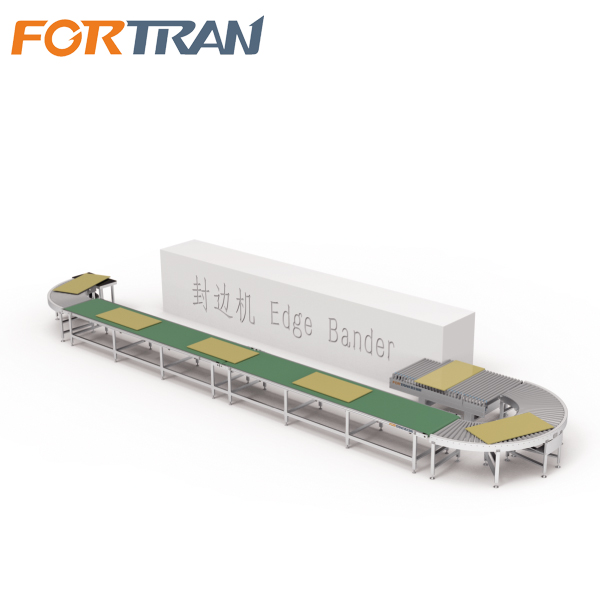

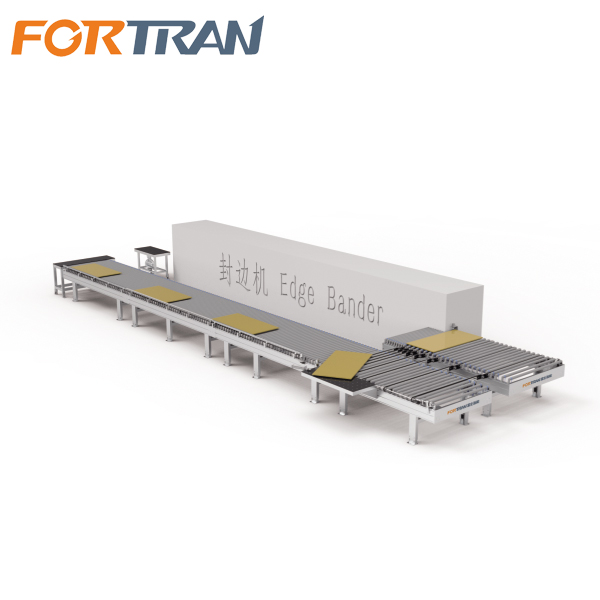

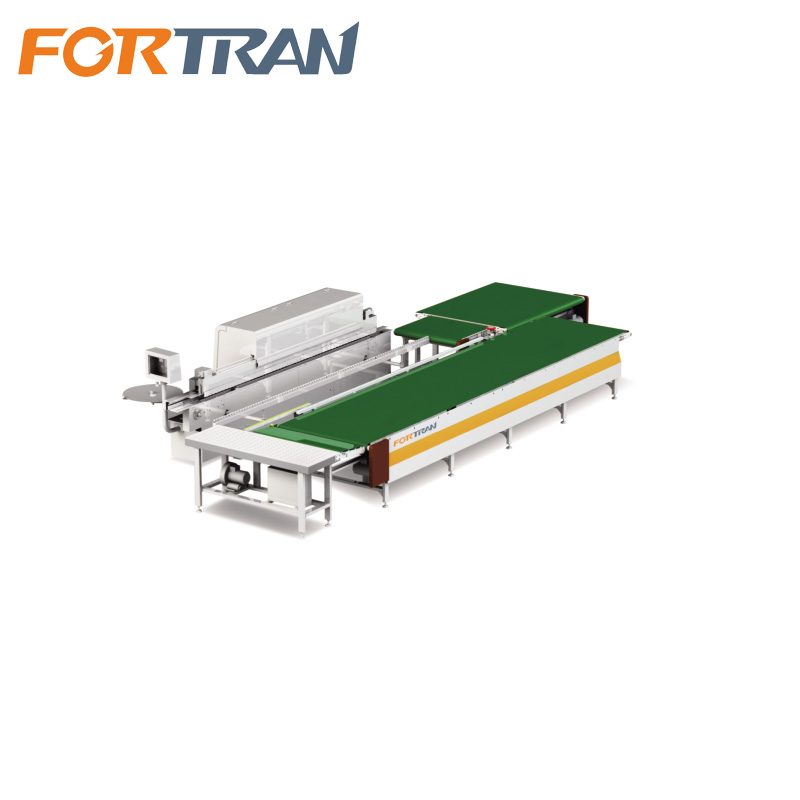

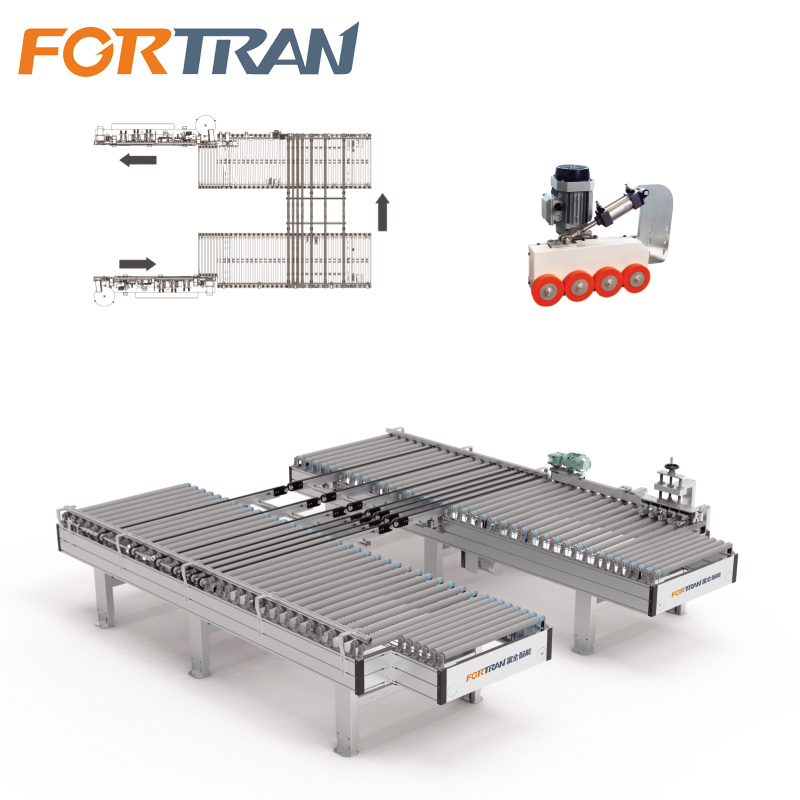

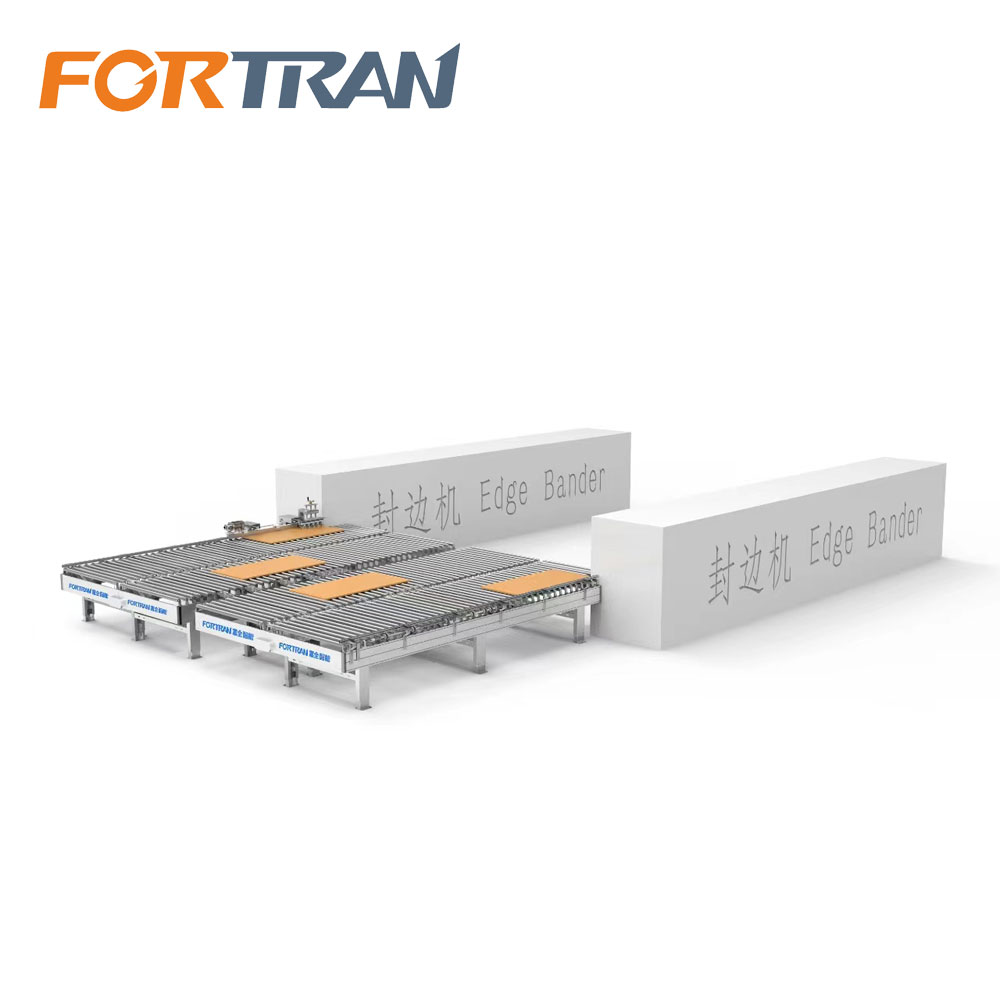

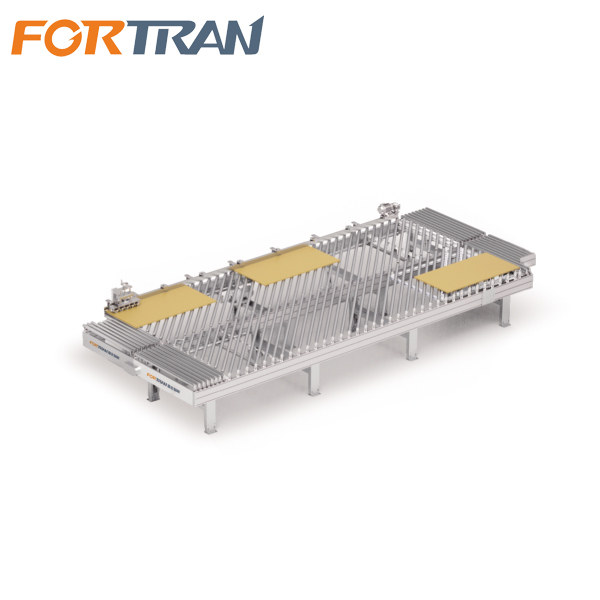

Panel Curved Returning System For Edge Banding MachineEnhance your edge banding process with our advanced Panel Curved Returning System, designed for seamless handling of curved and irregular panels. This innovative system ensures smooth, consistent edge application on rounded edges, eliminating gaps and imperfections. Key features include automatic panel detection, adjustable roller pressure, and synchronized feed mechanisms for flawless banding on concave/convex shapes. Made from high-durability materials, it withstands heavy-duty use while maintaining precision. Compatible with most edge banders, it reduces waste, improves productivity, and delivers professional-grade finishes on furniture, doors, and decorative panels. Upgrade your workflow with unmatched accuracy and speed!

Panel curved returning system for edge banding machineEdge Banding Machine Return ConveyorReturn Conveyorreturn conveyor for edgebanderEdge Banding Machine ConveyorEmailMore