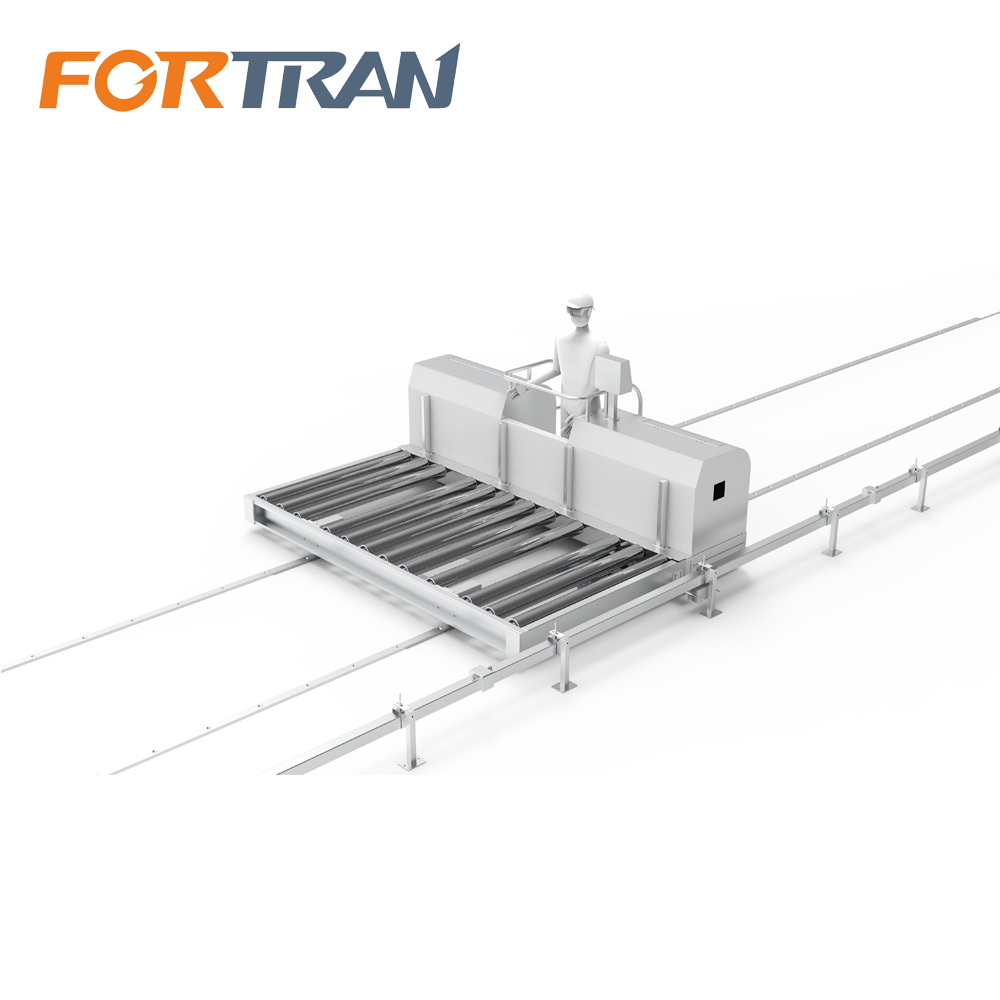

Smart Cache Warehouse✔ Automated Multi-Layer Caching – Multi-tier storage structure ensures smooth material flow between processes (cutting, edgebanding, drilling).

✔ High-Speed Plate Handling – Motor-driven lifting chain + roller conveyor system enables fast, stable plate transfer with precise positioning.

✔ Space-Saving Design – Compact vertical structure minimizes floor space while maximizing storage capacity.

✔ Seamless Integration – Compatible with CNC cutting machines, edgebanders, and drilling units for uninterrupted production.

✔ Smart Buffering Logic – Prevents production line congestion by temporarily storing panels during process delays.

✔ Durable Construction – Heavy-duty steel frame + wear-resistant sprockets/chains for long-term reliability.

✔ Reduced Manual Handling – Automated plate feeding/retrieval improves safety and efficiency.

Smart Cache WarehouseAutomatic Return Conveyorautomatic return conveyor lineSlat Belt Tray Return Conveyorreturn conveyor systemsEmailMore