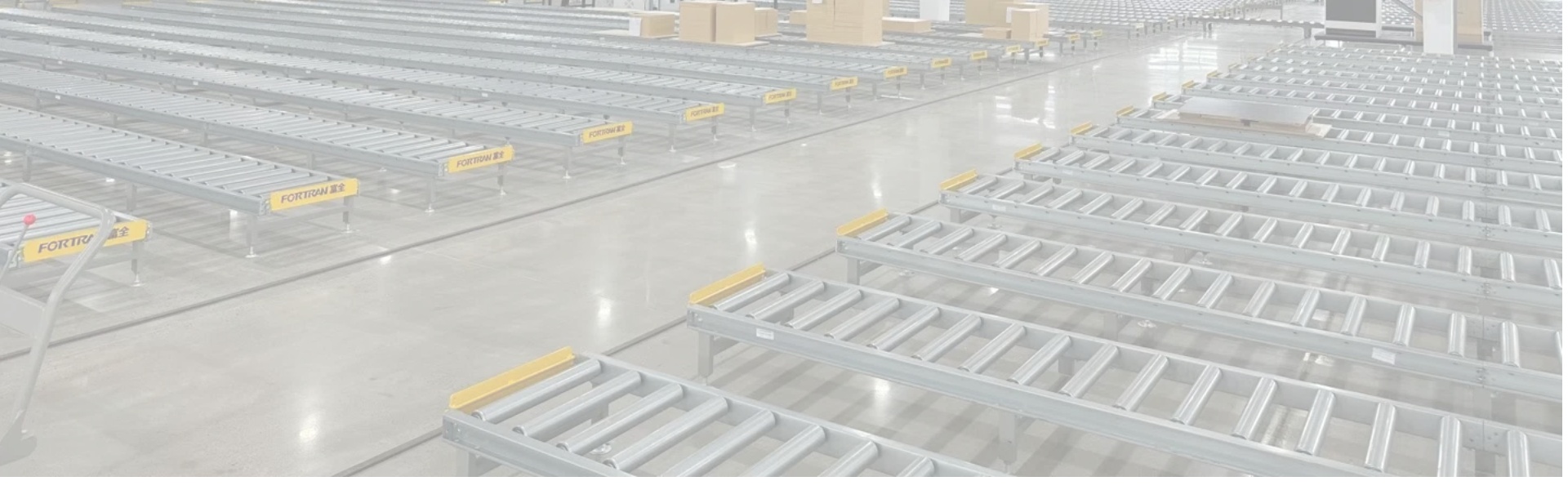

Panel Roller Transfer TrolleyThe panel roller transport vehicle, with its core advantages of "low cost, high flexibility, and easy operation", perfectly fills the application gap of large handling equipment in lightweight, short distance, and narrow environments, providing an economical and practical solution for efficient transportation of panel materials. It is an indispensable auxiliary tool in production, storage, decoration, and other scenarios.

Panel Roller Transfer TrolleyUnpowered Drum Conveyor LineRoller Hand Trolleyroller transfer conveyorEmailMore