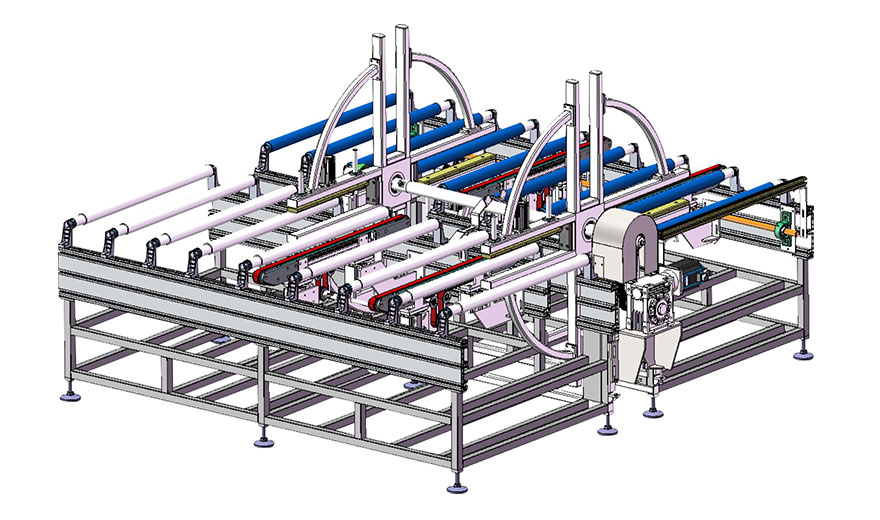

180 Degree Panel Turnover Machine includes cylindrical turnover machine, horizontal plate turnover machine, windmill-type turnover machine and sucker type turnover machine. Sucker type turnover machine is applicable to cutting section. Cylindrical turnover machine and windmill-type turnover machine are applicable to sander section. Horizontal plate turnover machine is applicable to automatic engraving system and automatic drilling machine.

a. Cylindrical turnover machine:

| Model | FQ-YFBJ24 |

| External Dimension | L3000/ 3500/ 4000*W2530*H1850mm |

| Panel length | 500-2400mm |

| Panel width | 300-1200mm |

| Panel thickness | 10-60mm |

| Loading capacity | 60kg/m2 |

| Total power | 3KW |

| Speed | 4-5 times/min |

| Working height | 900mm |

| Roller diameter | φ54 |

| Multiple groups of pneumatic grippers ensure stable clamping of panel |

| Safety device | anti-overshoot front gear |

| Main beam | high-strength square steel |

| Pneumatic component | AirTAC |

| Electric device | Schneider |

| PLC controlling system | Delta/ Inovance |

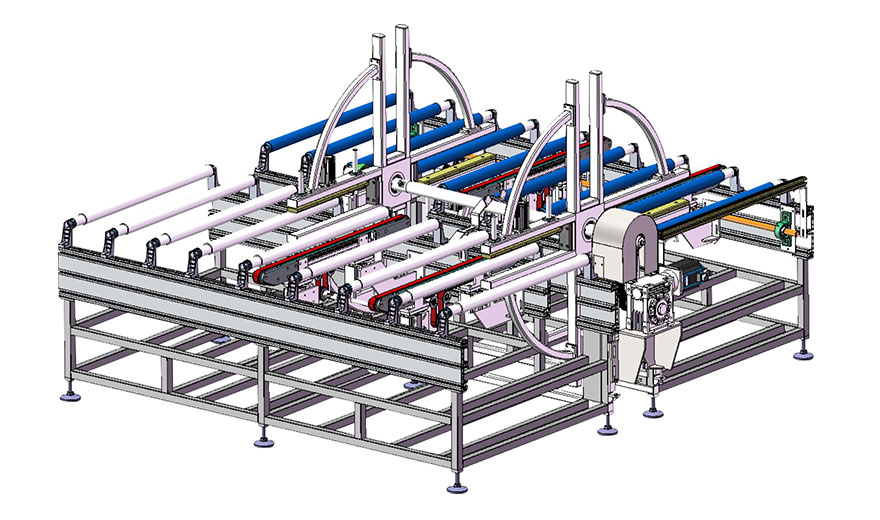

b. Horizontal plate turnover machine

| Model | FQ-HFBJ24 |

| External Dimension | L3500*W1415*H1300mm |

| Panel length | 400-2400mm |

| Panel width | 300-1200mm |

| Panel thickness | 10-60mm |

| Loading capacity | 50kg/m2 |

| Total power | 3KW |

| Speed | 4-5 times/min |

| Working height | 900mm |

| Translation belt | Shanghai Yongli |

| Main beam | high-strength square steel |

| Pneumatic component | AirTAC |

| Electric device | Schneider |

| PLC controlling system | Delta/ Inovance |

| Model | FQ-FBJ |

| External Dimension | L2000*W1650*H1800mm |

| Panel length | 400-2400mm |

| Panel width | 300-1200mm |

| Panel thickness | 10-60mm |

| Loading capacity | 80kg/m2 |

| Total power | 3KW |

| Speed | 4-5 times/min |

| Working height | 900mm |

| Main beam | high-strength square steel |

| Pneumatic component | AirTAC |

| Electric device | Schneider |

| PLC controlling system | Delta/ Inovance |

| Model | FQ-FZFB |

| External Dimension | L3000*W1300*H900mm |

| Panel length | 400-2400mm |

| Panel width | 300-1200mm |

| Panel thickness | 10-60mm |

| Loading capacity | 80kg/m2 |

| Total power | 3KW |

| Speed | 4-5 times/min |

| Working height | 900mm |

| Main beam | high-strength square steel |

| Pneumatic component | AirTAC |

| Electric device | Schneider |

| PLC controlling system | Delta/ Inovance |

3. Product Feature And Application

1.The main beam is made of high-strength aviation aluminum, which conforms to the international standard ICE 61131.

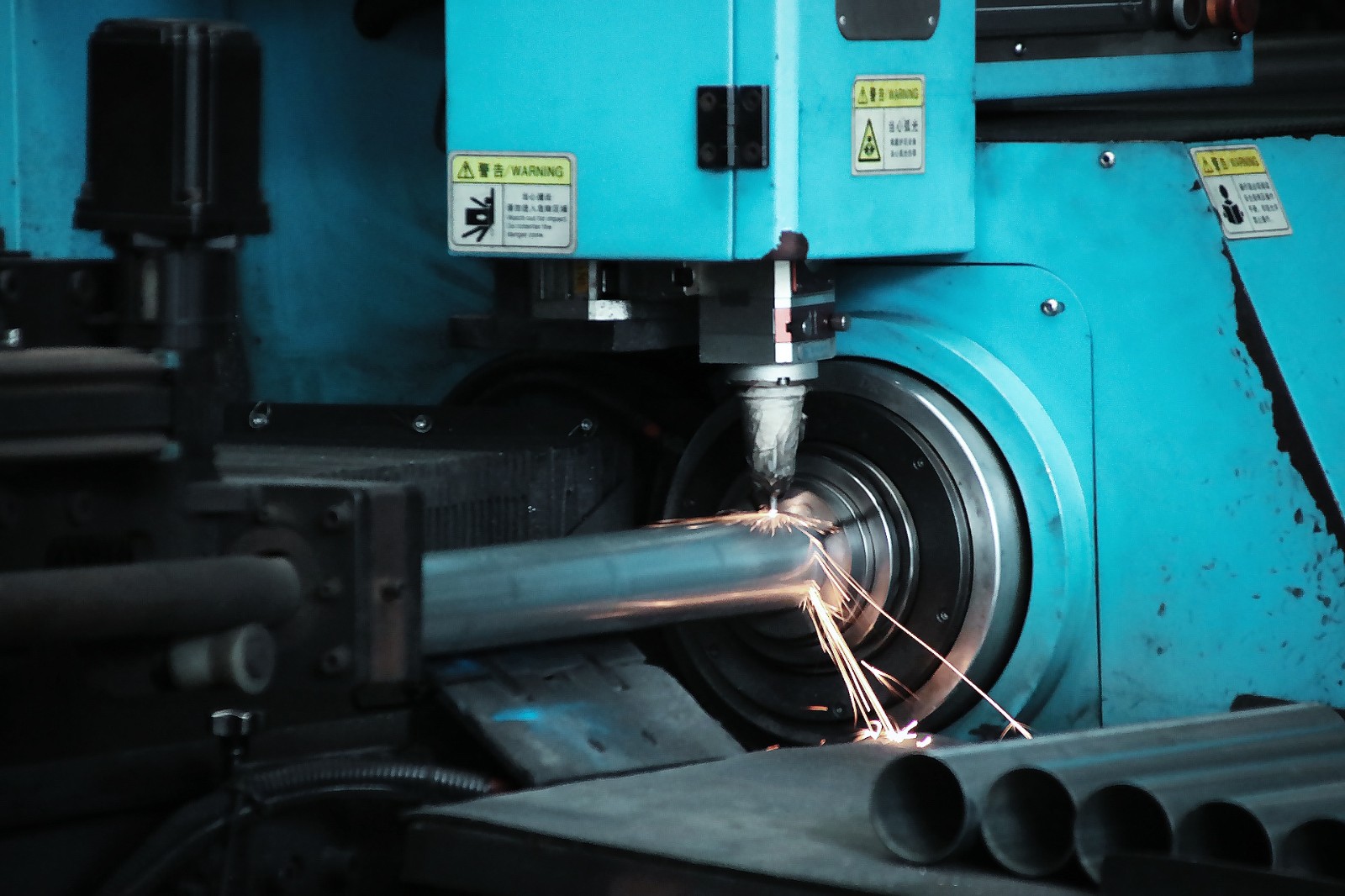

2.The joint part is precisely welded by Japanese OTC robot, which is corrosion-resistant and moisture-resistant for a longer service life.

3.The upper and lower parts of the drum are connected with synchronous chain transmission to ensure that the speed is consistent.

As a technology company that balances mechanical structure design and software development, FORTRAN stands out in the domestic automation field. It has outstanding technical strength and a large production scale. We focus on the research and development and production of automation equipment such as automatic loading and unloading equipment, automatic conveyor lines, elevators, paper cutters, case sealers, and box folding machines. These equipments play a vital role in industrial production and can effectively improve production efficiency and reduce labor costs. In addition to providing high-quality products, we also combine the actual situation of the customer's site to provide a complete customized automation solution. According to the specific needs of customers, we customize the most suitable automation equipment to ensure that customers achieve the greatest benefits in the production process.

We are well aware of the special requirements of the panel industry for "high cleanliness, high protection, and high efficiency" in the packaging process. Our professional team will go deep into the customer's production site and tailor the most suitable automation solutions based on different panel sizes, materials, and production capacity needs. From technical communication in the early stage to installation and debugging in the later stage, and then to continuous operation and maintenance support, we always walk side by side with our customers, providing professional and enthusiastic support for the intelligent production of panel enterprises

We have an ultimate pursuit of equipment quality, controlling every aspect from the source. The core components are selected from internationally renowned brands and undergo strict quality certification to ensure their stable and reliable performance. In the manufacturing process, we follow production standards that are higher than industry standards, and every process is strictly inspected by professional quality inspectors. From the machining accuracy of components to the assembly quality of the entire machine, we strive for excellence. Before leaving the factory, the equipment will undergo a continuous full load operation test for more than 1000 hours, simulating various complex production conditions to ensure that the equipment can be stably and efficiently put into use at the customer's site. With excellent quality, our equipment can adapt to the harsh environment of panel production workshops, effectively reducing downtime and maintenance costs, and bringing long-term stable benefits to customers.

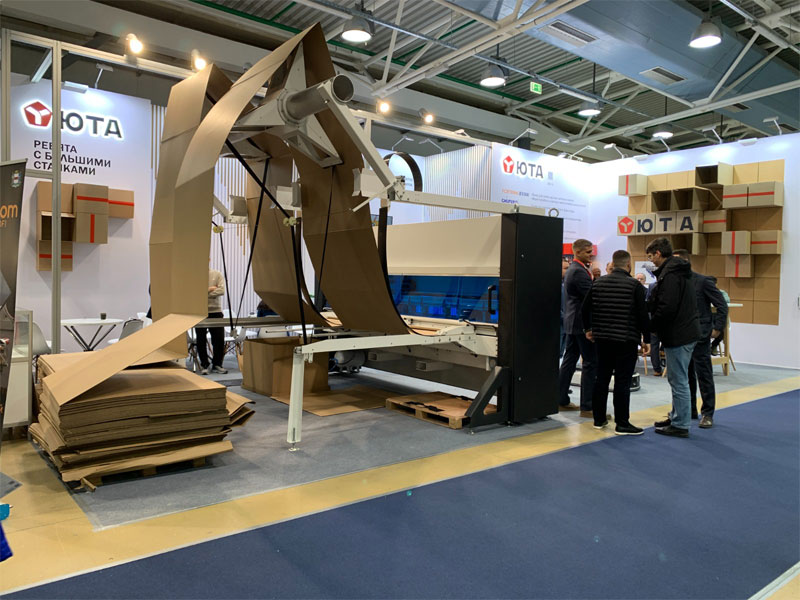

Through exhibition, we not only showcased the strength of our products, but also established close connections with customers from all over the world. This is not only a recognition of our products, but also a driving force for us to continuously improve quality and optimize services in the future. We look forward to working together with these new customers and welcome more partners with needs to contact us to create a better future for cooperation.

Our packaging materials comply with international standards and have sufficient strength and protective properties. In order to avoid damage to the goods during transportation, the packaging has good cushioning and shock resistance functions.

For long-distance transportation, use multimodal transportation to reduce cargo loss and transportation time