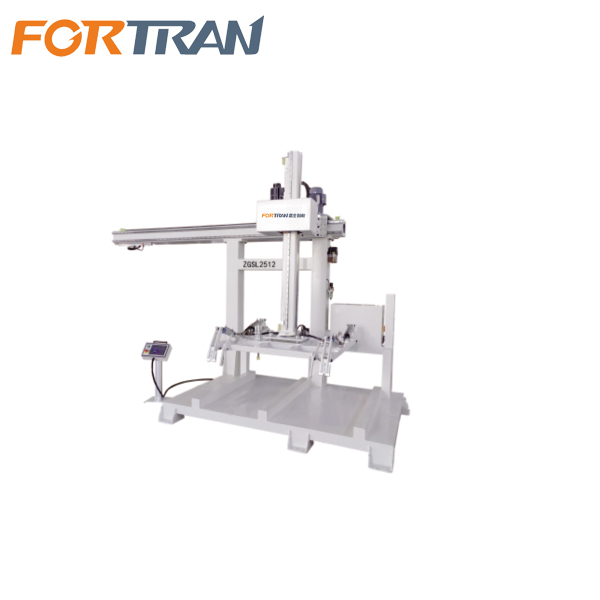

1.5 Tons E Type hydraulic Lifting Table

The 1.5-ton E-type hydraulic lifting platform, with the spatial advantage of the E-type structure, the stable performance of the hydraulic system, and the convenient design compatible with forklifts, accurately solves the problem of large, medium and heavy single piece materials entering and exiting the main machine. At the same time, it significantly reduces the labor intensity of workers through humanized operation design. For production enterprises that pursue "strong adaptability, efficient operation, safety and durability", it is not only a lifting device, but also a key assistance in improving production flow efficiency.

1.5 Tons E Type hydraulic Lifting Tabletable hydraulic lifthydraulic lift tablehydraulic scissor lift tablelarge lift table

Email

More