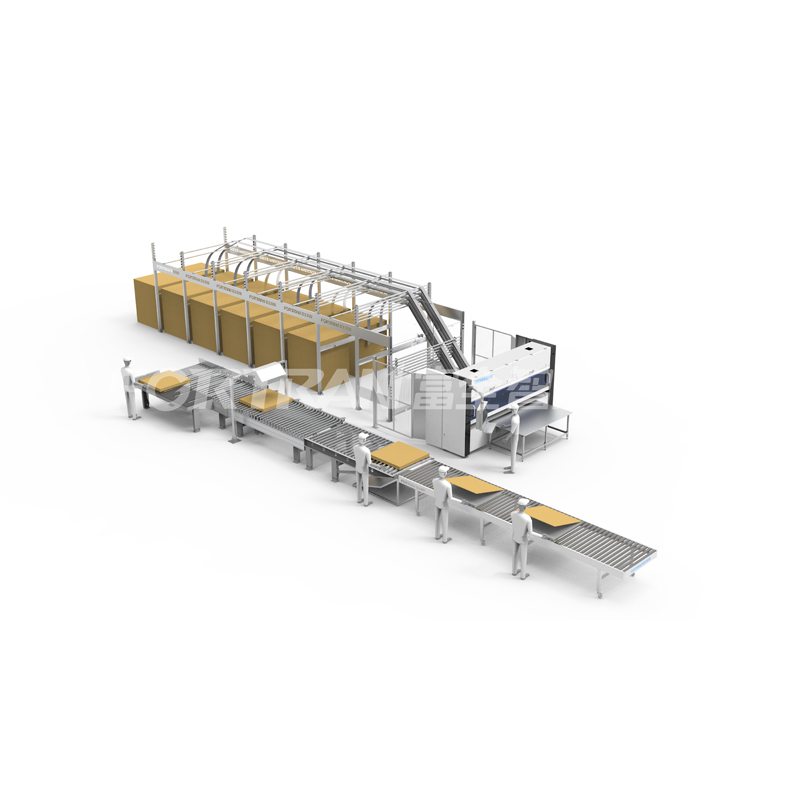

Sealing Packaging Production Line Solution

Equipment Overview

The Cutting-2518 Pro-3\6 Automatic Carton Cutting Machine is designed for the rapid production of corrugated boxes and related materials. With this equipment, you can choose from existing templates or create your own packaging type to produce the required packaging materials. The machine is designed to automate the packaging manufacturing process, making it as simple and convenient as possible. The Cutting-2518 Pro-3\6 can seamlessly integrate into production management systems and can also be manually operated with ease. The machine can receive tasks from various sources, requiring minimal operator involvement.

The focus of FORTRAN is on reducing packaging costs and minimizing waste—the machine automatically identifies the most suitable one of the six available cardboard formats for a specific product and switches to the most appropriate material. The Cutting-2518 Pro-3\6 can produce up to 8 boxes per minute per box type, which equates to 480 boxes per hour, and 3,840 boxes during an 8-hour shift.

2. Technical Description of the Sealing Packaging Production Line Solution

The operator loads one or more formats of Z-type cardboard (up to 6 formats can be loaded) into the corresponding unit of the machine and specifies the thickness of the loaded cardboard in the program so that the machine can account for the allowance.

The box manufacturing process can be carried out in one of the following ways

Receiving tasks from the operator:

After loading the cardboard, simply:

1. Select the desired box template;

2. Set parameters: length, width, height;

3. Start the machine.

Receiving tasks from the enterprise management system (1C, ERP, WMS, etc.)

The machine's software, BoxCutter, is based on the Windows operating system, allowing full utilization of modern equipment potential and enhancing the level of automation in the enterprise's production process. By placing the machine near the order sorting and packaging area, tasks can be sent directly from the enterprise management program to the machine, allowing sorters to receive the packaging they need, with the operator only needing to replenish the cardboard stock in time.

The Sealing Packaging Production Line Solution can also connect to a barcode scanner to obtain packaging by scanning product labels.

3. Main Technical Parameters

- Production capacity: Up to 8 boxes per minute

- Cardboard width: 350 to 2400 mm

- Recommended thickness: 3 to 6 mm

- Box length: From 120 mm

- Box width: From 120 mm

- Box height: From 18 mm

- Number of tools: 7+1

- Perforation function: Yes

- Automatic paper feeding: Can handle up to 8 cardboard formats

- Number of built-in templates: 4

- Template creation function: Yes

- Equipment dimensions: 14600 x 3900 x 3000 mm

- Equipment + 3 cardboard storage units: 2900 x 3500 x 11200 mm

- Equipment + 6 cardboard storage units: 2900 x 3500 x 16000 mm

- Equipment weight: 3200 kg

- Power requirements: 380V 50Hz, maximum power 9.15 kW

- Air pressure: 6~8 bar, 15-45 L/min

- Data interfaces: USB, RJ45, Wi-Fi

4. Main Component Descriptions

Cardboard Storage Unit (Option One Multi-Paper Library):

The Sealing Packaging Production Line Solution is equipped with 6 cardboard storage units, capable of loading 6 different widths of cardboard formats to minimize waste and reduce packaging costs. Each unit has a cardboard presence sensor that notifies the operator when the unit is empty.

Cardboard Storage Unit (Option Two Single Paper Library):

The Sealing Packaging Production Line Solution is equipped with 1 cardboard storage unit, capable of loading up to 2 cardboard formats with a width of up to 1220 mm, to minimize waste and reduce packaging costs. Each unit has a cardboard presence sensor that notifies the operator when the unit is empty. Additionally, if the vertical knife is equipped with 11 blades, up to 2 sheets of cardboard of the same specification can be cut simultaneously.

Automatic Paper Feeding System (Option One Multi-Paper Library):

The Sealing Packaging Production Line Solution will automatically select the most suitable cardboard format and switch to the required width. Switching cardboard formats only takes 4-6 seconds, with no operator involvement required.

Control Console

A modern industrial computer running the Windows operating system and BoxCutter software, easy to operate, allowing new users to get up to speed quickly. The software is prepared for integration with enterprise management systems to maximize automation of the packaging process.

Control and Power Components:

Electrical equipment, controllers, inverters, and other electronic devices are built into the machine, making it convenient and space-saving.

Longitudinal Cutting Unit:

The structure is lightweight and easy to disassemble. Each tool has an independent servo drive, enabling instantaneous size switching to ensure high precision. The rubber rollers are made from a special synthetic rubber material that prevents over-cutting and deformation during prolonged use, ensuring the durability of the equipment. Additionally, the cutting rollers and pressing rollers are of the same specification and material, allowing them to be interchanged after a period of use.

The transverse cutting knife only comes into contact with the cardboard. All cutting units are equipped with protective glass and safety devices, and the equipment will stop running when the tool unit is opened.

5. Product Advantages

-1. Unique tool structure design, integrated cutting technology, using a large pressing ring and small cutting knife, keeping the pressing and cutting on the same level, greatly reducing the chance of cardboard jamming.

- 2.The pneumatic components use FESTO cylinders and SMC high-speed solenoid valves, ensuring the accuracy of cardboard pressing and cutting, making the finished product aesthetically pleasing without defects. The Fuquan paper cutting machine also features a perforation function.

-3. The servo motor is equipped with the first-tier Chinese brand automation electrical control Huichuan, ensuring stable quality.

-4. The rubber roller is made of a special synthetic rubber material, ensuring durability with long-term use. The cutting roller and pressing roller are of the same specification and material, allowing them to be interchanged after a period of use.

-5. Self-developed software and cardboard optimization algorithms, with remote OTA update capability, and the number of boxes that can be cut can be freely added and set before leaving the factory.

-6. Fully servo longitudinal and transverse knife structure supports instantaneous arrangement of tool positions, ensuring maximum efficiency.

-7. The transmission structure of the transverse knife uses the highest grade ground rack, ensuring maximum stability and accuracy in the knife collection and start positions, more stable and better than belt transmission structures, as belt structures tend to extend and lengthen with prolonged use.

-8. Contains more than 20 commonly used carton specifications and allows for adding box types for cutting.

Cross-cutting/Folding Unit

The module is made of high-quality steel. The multi-functional cutting element - fully automated and easy to replace. The serrated blade - provides excellent cutting quality.

Longitudinal Cutting/Folding Unit

Multi-functional cutting element - fully automated and easy to replace. 7 longitudinal cutting/folding units are installed on the machine, providing twice the productivity and a high degree of flexibility. Lightweight structure, reducing the load on the guide rails and thereby minimizing wear.

Pneumatic System

The world-leading Festo brand pneumatic system The pneumatic system control is easy to operate and can set the required pressure quickly and accurately.

Control Panel

Control system based on industrial personal computers. Touchscreen interface and CBOX software. Quickly switch between different types and sizes of packaging.

6. Additional Options

The following options are not included in the delivery scope of the equipment but can be added to the order if needed:

Monitoring System:

Allows the collection of information on production time and downtime reasons, helping to understand production efficiency and make full use of the equipment, thereby improving employee efficiency.

Packaging Equipment

Automatic Three-Side Gluing Box Machine:

Production capacity: 4-8 times/minute

Box sizes that can be glued:

Length: 250-2800 mm

Width: 250-1200 mm

Height: 36-250 mm

Gluing station: ROBATECH GLUING SOLUTIONS

Automatic measurement and adjustment of box size: most suitable for small and medium batch production.

Cutting-2518 Pro-3\6 Automatic Carton Cutting Machine:

Number of tools: 8 + 1

Production capacity: Up to 8 boxes per minute

Automatic tool position adjustment: takes only 1-2 seconds

Box templates and sizes (length, width, height): adjustable on the console

Built-in box editor

Minimum box size: 120 x 120 mm

Minimum box height: 18 mm

Automatic paper feeding system: can handle up to 6 cardboard formats, minimizing raw material waste

Perforation function: available