As furniture manufacturing accelerates toward Industry 4.0, the concept of the “future factory” is no longer abstract. Digital twins, real-time visibility, and data-driven decision-making are becoming operational requirements rather than long-term visions. At the center of this transformation, the intelligent return conveyor system has emerged as a critical infrastructure layer—connecting machines, data, and workflows into a unified digital ecosystem.

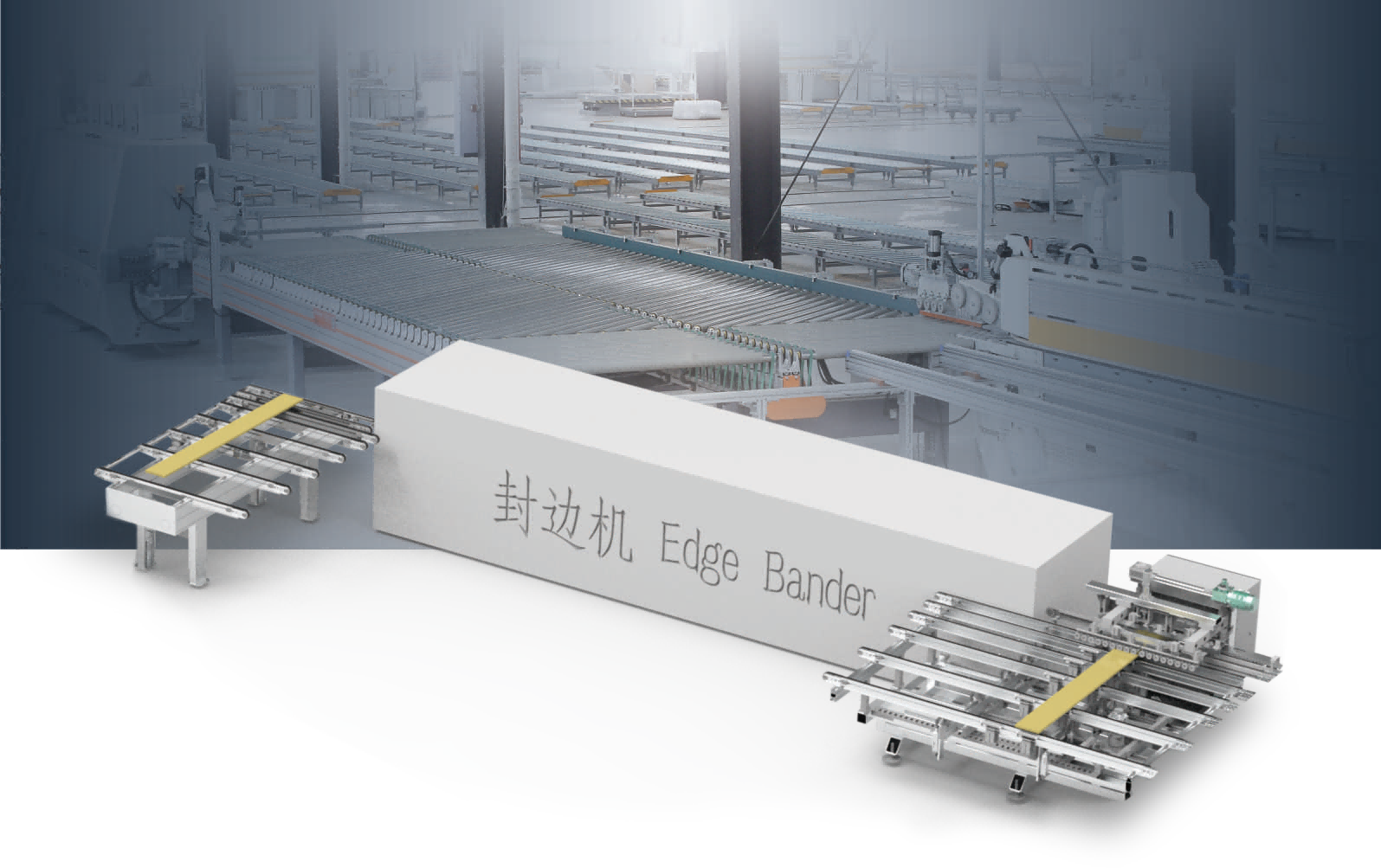

As a technology company that balances mechanical structure design with advanced software development, FORTRAN continues to help furniture manufacturers transform traditional workshops into intelligent, data-transparent factories. Among its core automation solutions, the Return Conveyor plays a pivotal role in reshaping edge banding lines, enabling digital twins, and supporting flexible manufacturing strategies.

From Material Flow to Data Flow: The Role of Conveyors in Digital Twins

In a digital twin environment, every physical action must generate data. The Edgebander Return Conveyor is no longer just a transportation device; it becomes a real-time data collection node. By tracking panel movement, cycle time, queue length, and equipment status, the conveyor system mirrors the physical production line in a virtual model.

This data foundation allows manufacturers to simulate production scenarios, identify bottlenecks, and optimize throughput before changes are made on the shop floor. When integrated with MES and ERP systems, the Return Conveyor transforms material circulation into digital intelligence.

Key Industry Pain Points Driving Digital Transformation

Furniture manufacturers worldwide face similar operational challenges:

Rising labor costs and skilled worker shortages

Increasing demand for mass customization

Limited visibility across production processes

Frequent line imbalance around edge banding stations

Traditional conveyor layouts lack flexibility and data connectivity. By contrast,Flexible Motorized Conveyors enable adaptive routing, dynamic buffering, and precise synchronization—key prerequisites for building a digital twin in furniture production.

How Intelligent Return Conveyors Enable Digital Twin Architecture

1. Data Collection at the Edge Banding Core

Edge banding is a critical quality-determining process. A return conveyor for edgebander captures process timing, panel ID, and routing logic in real time. This information feeds the digital twin, ensuring every panel’s journey is fully traceable.

2. Dynamic Flow Control for Flexible Manufacturing

With Flexible Edge Banding Solutions, manufacturers can support batch sizes as small as one piece. The digital twin dynamically adjusts conveyor logic, allowing the Return Conveyor to reroute panels based on order priority, machine availability, or quality inspection results.

3. Visualized Production and Transparent Factories

By combining sensors, RFID, and control software, the Edgebander Return Conveyor enables transparent factory operations. Customers can even view production progress online, aligning with the concept of an open, data-driven supply chain.

Industry Application Outlook

Mass Customization: One-piece flow supported by Flexible Motorized Conveyors

Transparent Factories: Digital twin dashboards powered by Return Conveyor data

Intelligent Decisions: AI-driven optimization using historical conveyor data

Supply Chain Collaboration: Data sharing enabled by return conveyor for edgebander systems

Performance Impact: Industry Analysis Table

| Indicator | Traditional Line | Intelligent Return Conveyor Line |

| Labor Requirement | High | Reduced by 70% |

| Line Balance Rate | 65–70% | Up to 93% |

| Order Flexibility | Limited | Fully Flexible |

| Data Availability | Fragmented | Real-Time |

| Digital Twin Readiness | Not Supported | Fully Enabled |

The combination of Flexible Edge Banding Solutions and intelligent conveyors creates measurable improvements across productivity, transparency, and responsiveness.

Why Chinese Automation Is Accelerating Digital Twins

FORTRAN leverages scalable manufacturing, modular design, and fast customization cycles to deliver advanced Return Conveyor systems at globally competitive costs. With proven experience in intelligent logistics and system integration, FORTRAN helps customers deploy digital twin-ready production lines without excessive investment or disruption.

Frequently Asked Questions (FAQ)

Q1: Can a return conveyor really support digital twin systems?

Yes. A modern Edgebander Return Conveyor collects structured data essential for virtual modeling and simulation.

Q2: Is this solution suitable for small factories?

Absolutely. Flexible Motorized Conveyors are modular and scalable, supporting gradual digital upgrades.

Q3: How complex is system integration?

FORTRAN systems support standard protocols, making return conveyor for edgebander integration with MES and ERP straightforward.

Q4: Does customization affect stability?

No. Flexible Edge Banding Solutions are engineered for stability even in highly customized layouts.

Call to Action: Build Your Digital Twin from the Ground Up

The digital twin does not begin with software—it begins with data. And data begins on the production line. By upgrading to an intelligent Return Conveyor, furniture manufacturers can establish the physical-digital bridge required for future-ready operations.

Conclusion: Conveyors as the Backbone of Smart Furniture Manufacturing

In the era of Industry 4.0, conveyors are no longer auxiliary equipment. The Return Conveyor, powered by intelligent control and data connectivity, has become the backbone of digital furniture manufacturing. Through Flexible Motorized Conveyors, Flexible Edge Banding Solutions, and intelligent system integration, manufacturers can unlock transparency, flexibility, and long-term competitiveness.

The future factory is built step by step—and it starts with a smarter way to move panels.