McKinsey once released a report stating that by 2030, 400-800 million jobs worldwide will be replaced by robots and automation, and over 375 million practitioners will switch careers and learn new skills due to automation. Artificial intelligence may rescue the furniture manufacturing industry, which is facing rising labor costs and worsening labor shortages, and help it remove the label of being "labor-intensive".

1.The Current Development Status of the Furniture Industry

The furniture industry is a traditional industry in China. After years of development, China has become a major furniture manufacturing and exporting country, as well as a leading furniture consumer in the world. It has become a backbone of the global furniture industry. However, there are phenomena in China's furniture industry, such as weak independent innovation capabilities in product research and development design, raw material supply and processing, production and manufacturing, low quality and efficiency levels, and insufficient depth of integration between the two industries. Causing problems such as product homogenization, insufficient supply of mid to high end products, and the need to improve product standards.

As the demographic dividend that previously drove rapid economic growth is gradually diminishing. The urgent problem that the furniture manufacturing industry needs to solve is how to cope with high labor costs. The rapid increase in domestic labor costs is an irreversible development trend, forcing the manufacturing industry to transform towards intelligent manufacturing. In the future, reducing the number of production workers, lowering direct labor costs, and improving company profitability through intelligent production will become one of the core competitiveness of the furniture manufacturing industry.

In the furniture manufacturing industry, the customization industry has a more urgent need for intelligent upgrading to solve the contradiction between personalization and industrialization. In the past, furniture companies were unable to solve the contradiction between personalized needs and industrial production during their expansion process, and traditional furniture customization had high costs. The development of customized furniture needs to address this pain point the most. The core of the industrial model is shifting from "product centered" to "user centered", from large-scale assembly line production to customized scale production, and from production-oriented manufacturing to service-oriented manufacturing. Only by relying on intelligent manufacturing can customized scale development be achieved. Intelligent, information-based, and refined manufacturing can achieve a perfect integration of personalization and industrialization. The intelligent upgrade will bring advanced flexible production lines and higher utilization rates of sheet materials; High degree of automation, reducing labor costs, improving supply chain efficiency, and breaking away from labor-intensive traditional production methods.

At present, in the entire furniture industry, there are many product varieties, including panel furniture, soft pack furniture, solid wood furniture, and hardware furniture, each with vastly different production processes and procedures. The production of each product involves more than ten stages, and it is impossible to use automated assembly lines all at once. Only partial implementation of numerical control and automation can be achieved first. In some furniture factories, machines play a leading role in cutting, drilling, packaging, and warehousing, and the automation level of the factory has reached over 60%.

2.Fortran Intelligence Helps Enterprises Achieve Automation

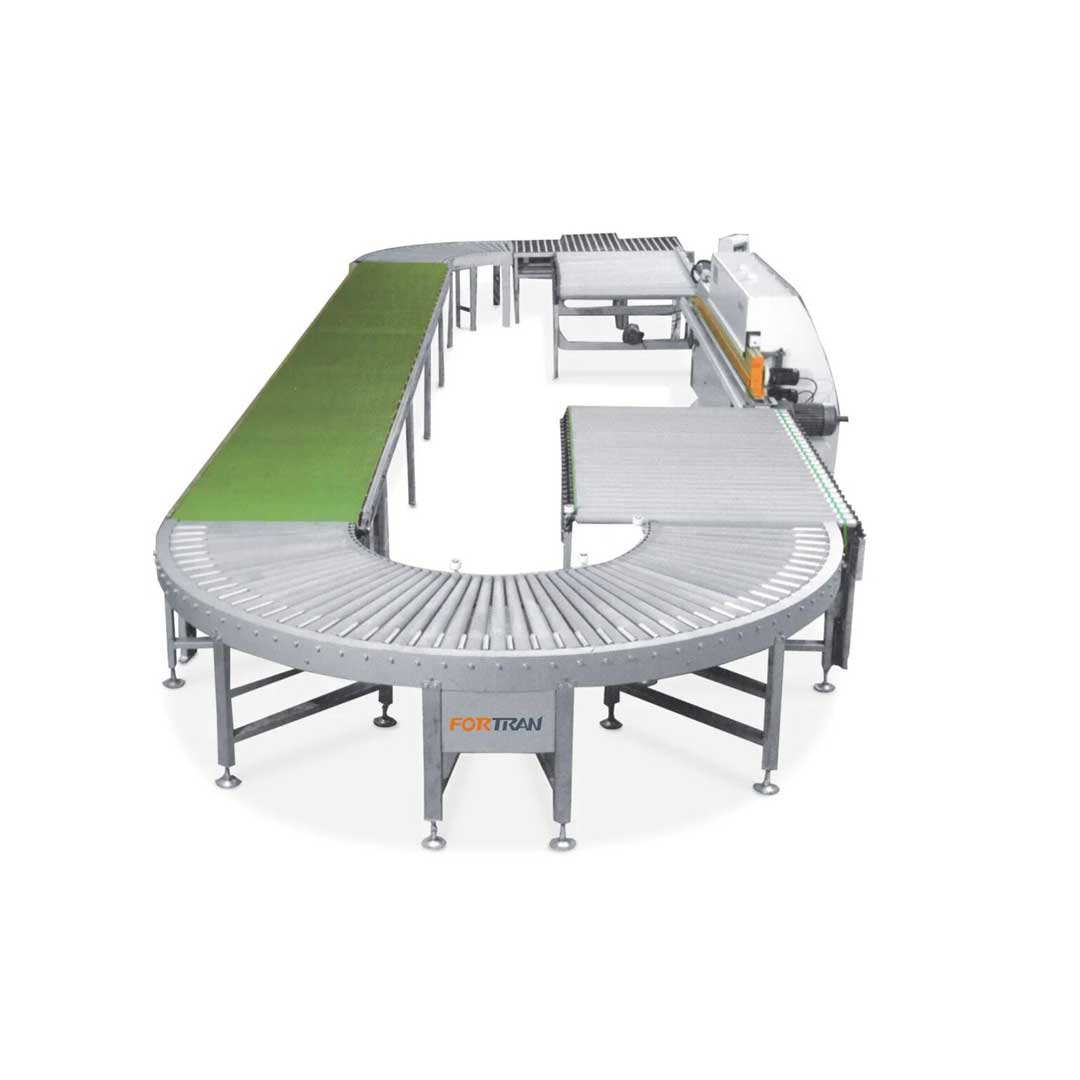

Fuquan Intelligent focuses on the production and manufacturing of automation equipment including automatic loading and unloading equipment, automatic conveyor lines, elevators, etc., and independently develops and produces industrial rollers to solve production line quality problems from the root. We provide customers with personalized and customized complete automation solutions from the aspects of processing and production, auxiliary loading and unloading, and post production automation implementation based on their on-site needs.

Under the impact of the epidemic and the overall environment, we provide free planning and production process advice services to our clients, helping them reduce labor costs to the greatest extent possible and enhance their competitiveness and advantages in the market.

Plate Batch Production Line

Capacity output: 9600 square meters per day

Transportation method: Automated transfer transportation

Features of the entire production line: integration with MES and ERP management systems, connection of intelligent edge banding machines, unmanned drilling and milling, intelligent sorting, realizing the integration of front-end and back-end production for customized home furnishings.

Electronic Saw Workstation

According to the Mes System Order, Cut the Required Specifications

Cutting Buffer Workstation

Cache the Boards to Be Sealed After Cutting

Automatic Edge Banding Workstation

Complete the Four Edge Sealing of the Board Through Automated Wiring, Saving Labor, Reducing Handling, And Improving Efficiency to 200%.

Automatic Drilling and Milling Workstation

After the Edge Sealing of the Board Is Completed, It Automatically Enters the Six Sided Drilling Connection System, Achieving Unmanned Operation.

Sorting Output Workstation

After the Drilling of the Board Is Completed, It Is Automatically Sorted into Packages or Orders Through the Sorting System According to the Order.

Connection plan

In addition to the intelligent integrated connection solution, Fuquan Intelligence also provides production process connection solutions for various sections of the furniture factory, such as cutting section connection, edge sealing section connection, drilling section connection, sorting section connection, wooden door section connection, etc., which saves labor costs, improves work efficiency, ensures stable and fast production, and doubles production capacity and profit.

Pre Feeding Scheme for Electronic Saw

Edge Banding Machine Connected in the Same Direction

Edge Banding Machine Curved Turning Line

Drilling Automatic Loading and Unloading Line

Device Application

Reliable equipment is necessary to ensure more stable operation of unmanned connections. In order to ensure reliable and stable quality, Fuquan Intelligence adheres to independent research and development, production, and strictly follows the standard quality management system from cutting, assembly, quality inspection, testing, and factory delivery. Compatible design matching, perfectly matching every aspect of furniture production technology.