-

Home

-

Products

-

Intelligent Factory Furniture Production Line

-

Panel Automatic Packaging Line

-

Automatic Carton Packaging Equipment

-

Edge Banding Machine Automatic Return Conveyor

-

Automatic Gantry Loader And Unloading Machine

-

Furniture Production Line Dust Cleaning Machine

-

Panel Hydraulic Lifting Table

-

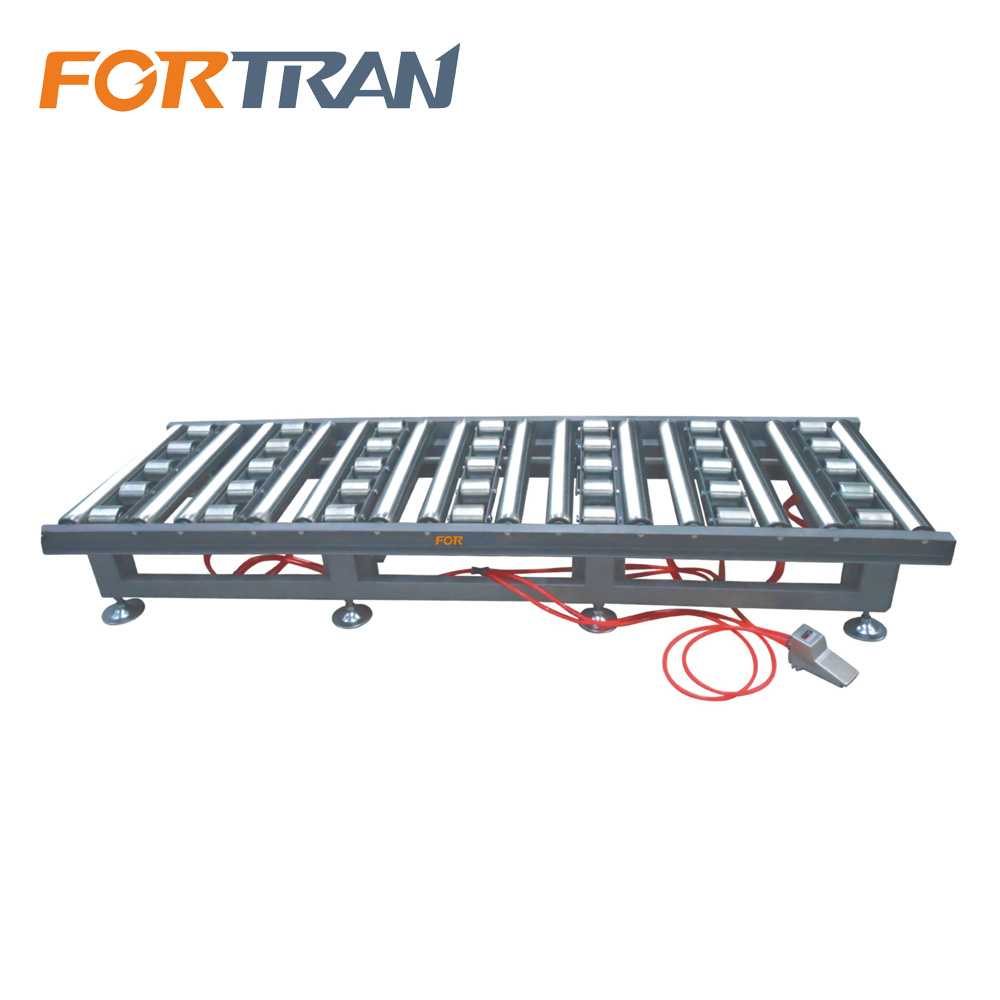

Panel Roller Conveyor System

-

Panel Manual Roller Conveyor Line

-

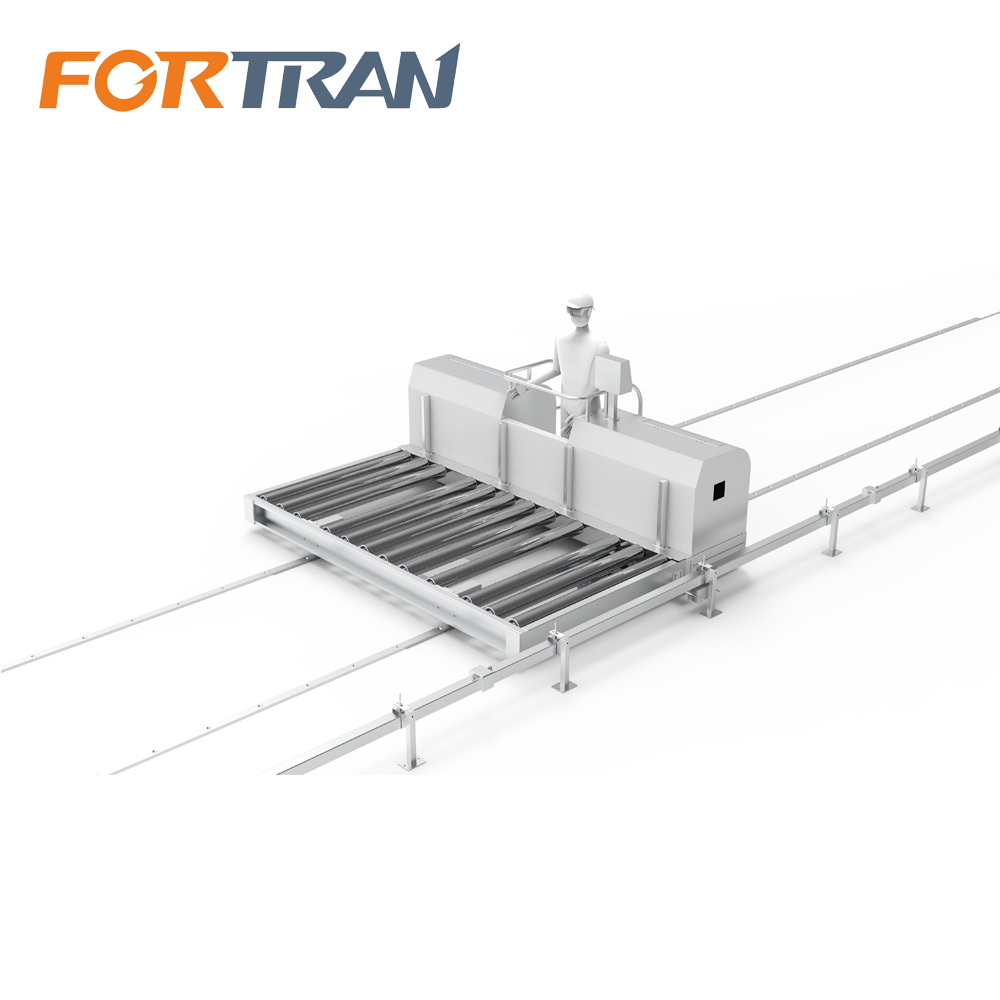

Automatic Return Conveyor

-

Intelligent Factory Furniture Production Line

- News

-

Case

- Factory Show

-

Contact Us

- About Us