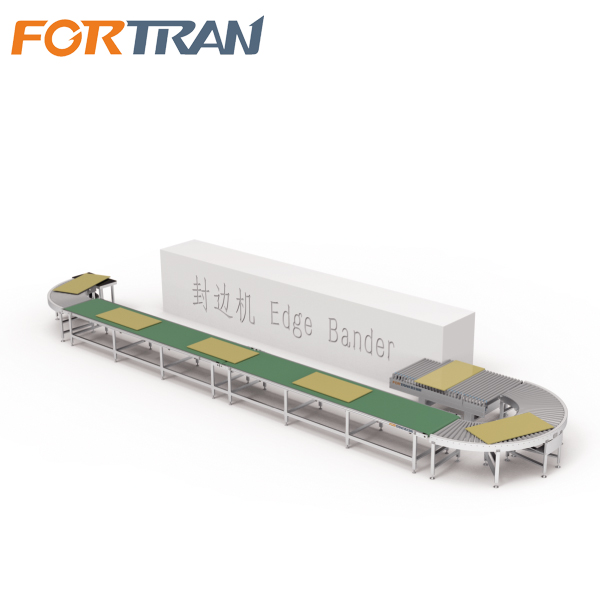

Cabinet Assembly Machine

The cabinet assembly rack of this device adopts integral welding technology, which has extremely high strength and can ensure stable and reliable overall operation. During the feeding process, the use of photoelectric detection technology not only ensures high precision and efficiency, but also significantly reduces the possibility of faults occurring. The mechanical positioning device uses guide rails, which have the characteristics of high accuracy and low vibration, significantly extending the service life of the equipment. The transmission system cleverly combines gears, chains, and belts, while the positioning function is achieved by servo motors, which have the characteristics of precision, efficiency, and speed, as well as the advantages of high torque and compact size, further improving the overall performance of the equipment.

Cabinet Assembly MachineCNC Woodworking MachinesWood Processing MachinesWoodworking Machinery

Email

More