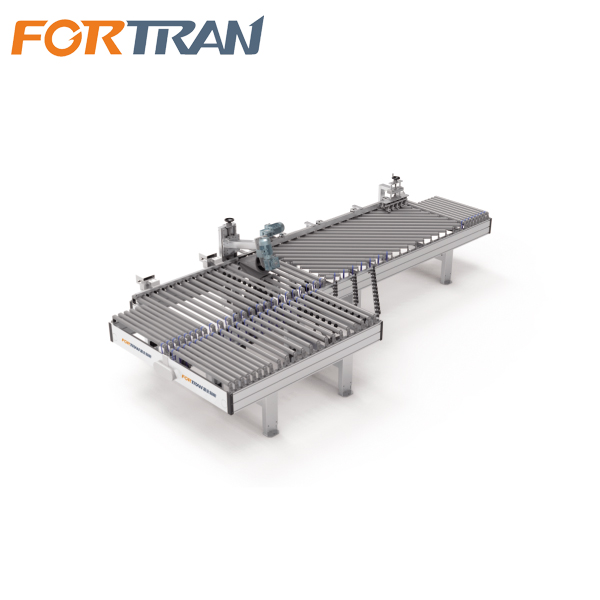

Powered Belt Lifting Table

The electric belt lifting platform, with "flexible protection of belt transmission" and "precise control of electric lifting" as its core, perfectly fills the equipment gap of lightweight material cross height circulation. Its friendliness towards vulnerable materials, adaptability to clean environments, and improvement in operational efficiency make it an ideal choice for flexible production lines in industries such as e-commerce, food, and electronics. Choosing it is not only about introducing a transmission lifting device, but also injecting a "smooth, efficient, and clean" solution for lightweight material processing, helping enterprises optimize processes and reduce costs.

powered belt lifting tableLifting Tablebelt lifting tableElectric Belt Lifting Platformlifting table

Email

More